Trenchless sewer restoration using the UV Liner method

The unique UV Liner technology is a trenchless sleeve method which originates from Germany. This method of sewer restoration enables clean and rapid renewal of piping with circular and oval profiles. It significantly reduces the time required for restoration and is environmentally friendly.

PIPE TYPES SUITABLE FOR THIS METHOD

The UV Liner method is suitable for the trenchless restoration of pipes with a DN 150 mm to 1,200 mm circular profile and a DN 200/300 to 800/1200 mm oval profile. With pipes of up to 400 mm in diameter, the refurbishment work progresses as rapidly as 200 metres in 6 hours. For pipes with a diameter exceeding 500 mm, we can restore 200 metres in 10 hours using this technology.

PROPERTIES OF THE UV LINER SLEEVES

The excellent mechanical properties of the liner allow for use under high pressure whilst reducing the thickness of the sleeve wall. The liner’s smooth surface and thin wall considerably improve the pipe’s hydraulic properties. The sleeve can take high external and internal loads.

HOW IT WORKS

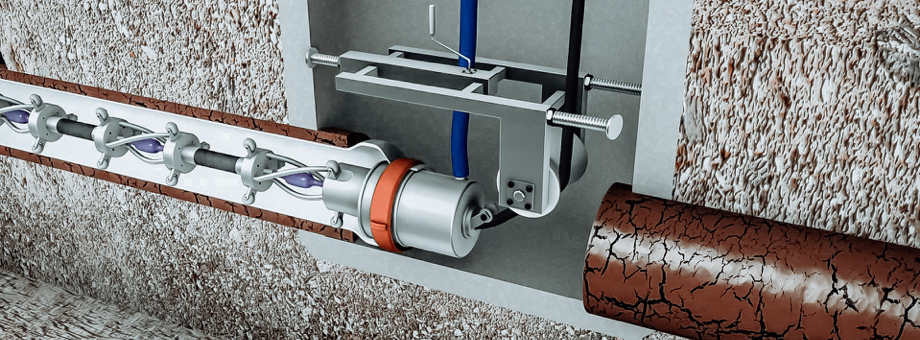

A seamless glass fibre liner saturated with a polyester or vinyl ester resin is drawn into the pipe to be restored and pressurised with air. The resin contained in the sleeve is cured using UV lamps. As a result, an entirely new, self-supporting plastic pipe is created within an old sewer.

INSTALLATION PROCESS

- Opening access to the pipe from both sides

- Video inspection and cleaning of the pipe to be restored

- Induction of the resin-saturated sleeve into the pipe

- Pressurising the sleeve with air

- Curing the resin using UV lamps

- De-pressurising the sleeve and cutting off the ends

- Cutting open service pipes and cleaning the pipe inside manholes

- Video inspection recorded on CD or DVD

- Commissioning

BENEFITS OF THE UV LINER METHOD

- Provides a pipe with full structural integrity.

- It improves the pipe’s hydraulic properties, increasing its flow rate and sealing it completely.

- The cured liner is resistant to abrasion and chemicals.

- Pipework can be restored at a rate of up to 500 metres per day and the process is environmentally friendly.

- It can extend a pipe’s service life by as much as 80 years.

Resins used: polyester, vinyl ester

Liner wall thickness: approx. 3.5–18 mm

Short-term E-modulus: 9,500 N/mm2

FURTHER DETAILS ABOUT THE TECHNOLOGY

- We always manufacture the sleeves to a precisely calculated thickness which conforms to the dimensions of a specific pipe (circumference, DN, length).

- We determine the thickness of the liner wall based on a structural calculation that takes into consideration the pipe’s profile, degree of damage, and installation depth, as well as groundwater level.

- During the pressurising and curing process, we monitor and record essential parameters. Once the sleeve is cured, the parameters are available as an official record.

- Once the process is finished, the robotic cutting device re-opens the covered branch pipes. If requested, we can fit the connection of the branch pipe to the sewer with a hat. Branch pipes can be reopened manually in man-sized pipes, including bricklayer work.

Once the work inside the pipe is completed, we inspect the pipe using cameras and save the video recording.

OUR CERTIFICATION

We hold EN ISO 9001:2008 and EN ISO 14001:2004 quality certification.

Certificate No. 204/C5a/2013/090-030016 for the product Restoration Liner for Sewer Pipe Systems and Industrial and Raw Water Supply Pipes – UV LINER System, dated 22 August 2013 (Technical and Test Institute for Construction Prague).

ITC Certificate Ref. 313500374/03 Resistance to Chemical Effects at Constant Deformation.